Audi Q3: Instrument Cluster

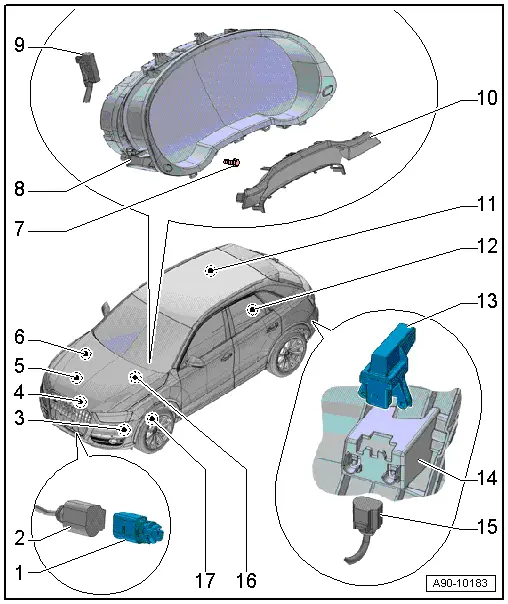

Overview - Instrument Cluster

1 - Outside Air Temperature Sensor -G17-

- Removing and installing. Refer to → Chapter "Outside Air Temperature Sensor, Removing and Installing".

2 - Connector

- For Outside Air Temperature Sensor -G17-

3 - Windshield Washer Fluid Level Sensor -G33-

- Removing and installing. Refer to → Chapter "Windshield Washer Fluid Level Sensor, Removing and Installing".

4 - Oil Level Thermal Sensor -G266-

- Removing and installing. Refer to → Rep. Gr.17; Oil Pan/Oil Pump; Oil Level Thermal SensorG266, Removing and Installing.

5 - Oil Pressure Switch

- Removing and installing. Refer to → Rep. Gr.17; Oil Filter/Oil Pressure Switch.

6 - Engine Coolant Level Warning Switch -F66-

7 - Bolt

- 3 Nm

- Quantity: 2

8 - Instrument Cluster

- With Instrument Cluster Control Module -J285-

- Removing and installing. Refer to → Chapter "Instrument Cluster with Instrument Cluster Control Module -J285-, Removing and Installing".

- Multi-pin connector pin assignment. Refer to → Chapter "Instrument Cluster Multi-Pin Connector Contact Assignment".

9 - Connector

- For instrument cluster

10 - Gap Cover

- Removing and Installing. Refer to → Body Interior; Rep. Gr.68; Storage Compartments/Covers; Instrument Cluster Gap Cover, Removing and Installing.

11 - Fuel Level Sensor -G-

- Connector assignment. Refer to → Chapter "Fuel Level Sensor -G- Connector Assignment".

- Removing and Installing. Refer to → Rep. Gr.20; Fuel Delivery Unit/Fuel Level Sensor; Fuel Level SensorG Removing and Installing.

12 - Fuel Level Sensor 2 -G169-

- Connector assignment. Refer to → Chapter "Fuel Level Sensor 2 -G169- Connector Assignment".

- Removing and installing. Refer to → Fuel Supply System; Rep. Gr.20; Fuel Delivery Unit/Fuel Level Sensor; Fuel Level Sensor 2G169, Removing and Installing

13 - Radio Frequency Controlled Clock Receiver -J489-

- Removing and installing. Refer to → Chapter "Radio Frequency Controlled Clock Receiver, Removing and Installing".

14 - Mount

- Integrated in the bumper cover

15 - Connector

- For Radio Frequency Controlled Clock Receiver -J489-

16 - Brake Fluid Level Warning Switch -F34-

- Removing and Installing. Refer to → Break System; Rep. Gr.47; Overview - Brake Booster/Brake Master Cylinder.

17 - Left Front Brake Pad Wear Sensor -G34-

- Removing and installing. Refer to → Brake System; Rep. Gr.46; Front Brakes; Brake Pads, Removing and Installing.

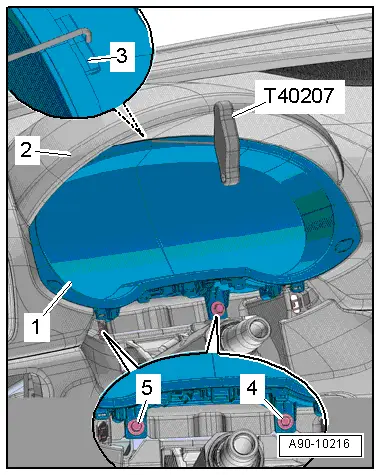

Instrument Cluster with Instrument Cluster Control Module -J285-, Removing and Installing

Special tools and workshop equipment required

- Hook Tool -T40207-

Note

Note

- All warning lamps in instrument cluster are fitted with light-emitting diodes. Instrument cluster must be replaced in the event of warning lamp failure.

- Do not disassemble the instrument cluster.

- It is not necessary to remove the steering wheel in order to remove the instrument cluster.

- If replacing the control module, select the "Replace Control Module" function Vehicle Diagnostic Tester.

Removing

- Adjust steering wheel downward and to rear as far as possible, use entire adjustment range of steering column adjustment for this.

- Turn off the ignition.

- Vehicles with ignition lock: Remove the key.

- Remove the gap cover and place on the upper steering column trim panel. Refer to → Body Interior; Rep. Gr.68; Storage Compartments/Covers; Instrument Cluster Gap Cover, Removing and Installing.

- Remove the bolts -4 and 5-.

- Guide the Hook Tool -T40207- carefully between the instrument panel -2- and the instrument cluster -1- and engage from behind in the pull tab -3-.

- Pull the instrument cluster out just far enough until it is touching the steering wheel.

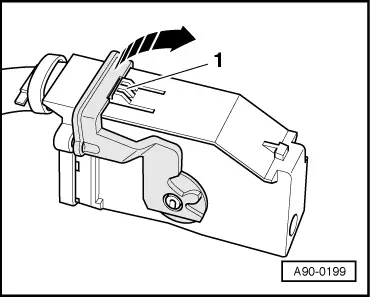

- Disconnect the connector.

- To disconnect the connector, press the tab -1-, turn the retaining bracket in direction of -arrow- and remove the connector.

- Remove the instrument cluster on the driver side between the steering wheel and the instrument panel.

Installing

Install in reverse order of removal. Note the following:

- Follow the instructions on the Vehicle Diagnostic Tester display with a new instrument cluster.

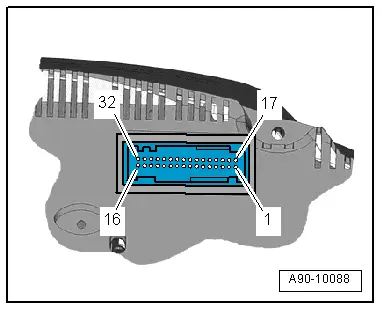

Instrument Cluster Multi-Pin Connector Contact Assignment

32-Pin Connector, Gray

1 - Fuel Level Sensor -G- - full

2 - Fuel Level Sensor -G- - empty

3 - Fuel Level Sensor 2 -G169- - full

4 - Fuel Level Sensor 2 -G169- - empty

5 - Radio controlled clock signal

6 - Radio Frequency Controlled Clock 5 V

7 - Transponder 1

8 - Transponder 2

9 - Not Assigned

10 - Not Assigned

11 - Oil Level Thermal Sensor -G266-

12 - Not Assigned

13 - Not Assigned

14 - Not Assigned

15 - Brake pad

16 - Terminal 31

17 - Windshield Washer Fluid Level Sensor -G33-

18 - Engine Coolant Level Warning Switch -F66-

19 - Outside Air Temperature Sensor -G17-

20 - Sensor ground

21 - Not Assigned

22 - Not Assigned

23 - Not Assigned

24 - Not Assigned

25 - Electromechanical Parking Brake Control Module -J540- signal

26 - Brake Fluid Level Warning Switch -F34-

27 - Oil pressure

28 - Instrument cluster CAN bus High

29 - Instrument cluster CAN bus Low

30 - Not Assigned

31 - Not Assigned

32 - Terminal 30