Audi Q3: Wheel Bearing Housing Bonded Rubber Bushing, Replacing

Wheel Bearing Housing Bonded Rubber Bushing, Replacing, FWD Vehicles

Special tools and workshop equipment required

- Bearing Installer - Control Arm -3346-

- Bearing Installer - Carrier Bearing -3350-

- Fitting Sleeve -3378-

- Torque Adapter -3390-

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Remove the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- Remove the wheel bearing/wheel bearing unit. Refer to → Chapter "Wheel Bearing Unit, FWD, Removing and Installing".

- Remove the brake shield. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Shield, Removing and Installing.

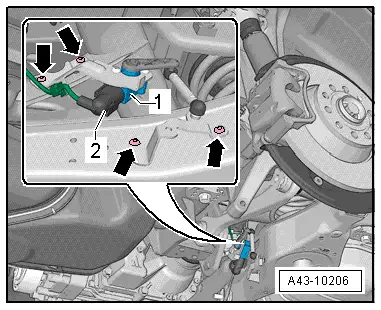

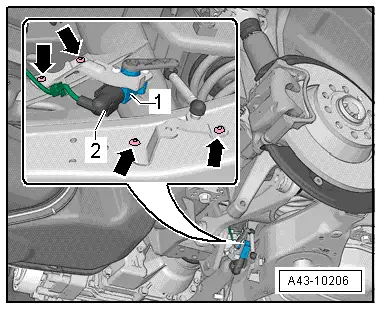

- Remove the bolts -lower arrows- on vehicles with level control system sensor.

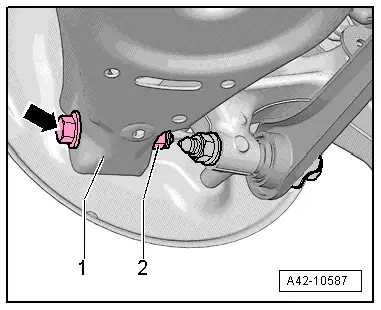

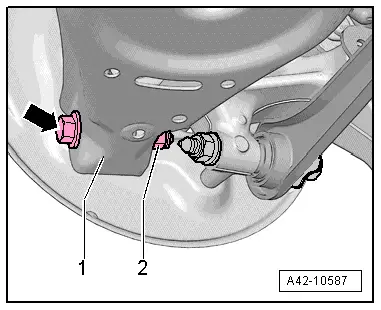

- Remove the nut -2- and remove the bolt -arrow- for the lower control arm -1-.

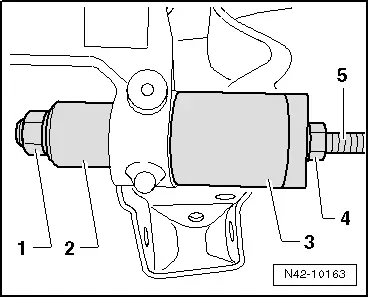

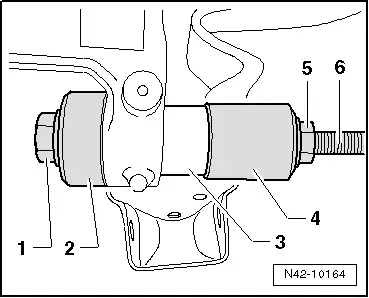

Pressing out bonded rubber bushing

1 - Bearing Installer - Control Arm - Nut -3346/3-

2 - Torque Adapter -3390-

3 - Bearing Installer - Carrier Bearing -3350-

4 - Nut, commercially available

5 - Bearing Installer - Control Arm - Spindle -3346/2-

- Remove bonded rubber bushing by turning spindle.

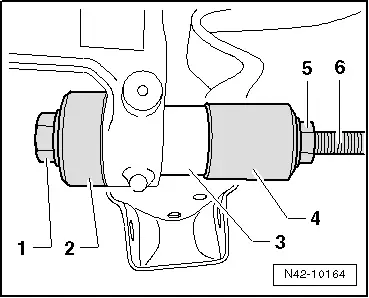

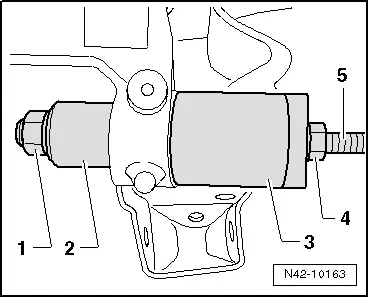

Installing the bonded rubber bushing

1 - Bearing Installer - Control Arm - Nut -3346/3-

2 - Bearing Installer - Control Arm -3346-

3 - Bonded rubber bushing

4 - Fitting Sleeve -3378-

5 - Nut, commercially available

6 - Bearing Installer - Control Arm - Spindle -3346/2-

- Install bonded rubber bushing by turning support arm bearing installation tool.

Note

Note

- Do not use lubricant!

- Insert bearing with care so it is not canted.

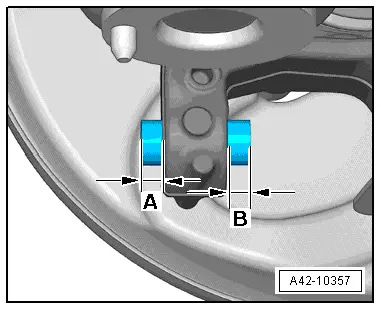

- Check the installed position after installing the bonded rubber bushing.

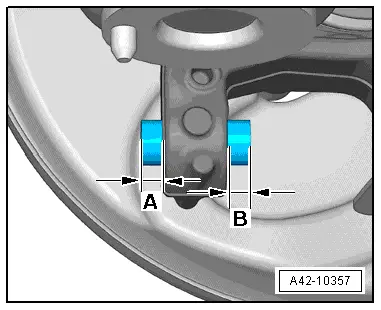

- Dimensions -A- and -B- must be the same (each measured, if applicable, at a spot where there is no seam/burr).

- Install the bonded rubber bushing again if dimensions -A- and -B- are different.

Use a commercially available 27 mm socket wrench in place of the Fitting Sleeve -3378- to install the bonded rubber bushing.

Installing

Installation is reverse of removal, noting the following:

Bolting at wheel bearing housing may only occur when the dimension between wheel hub center and lower edge of wheel housing, measured before assembly, is achieved. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Install the brake caliper. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Caliper, Removing and Installing.

- Install the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

- On vehicles with electronically controlled damping, perform the function "Adapt the control position" with the Vehicle Diagnostic Tester.

- If the control position was reprogrammed and if the vehicle has lane assist, then it will then be necessary to calibrate the driver assistance systems front camera. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".

- On vehicles with level control system sensor, perform headlamp basic setting. Refer to → Electrical Equipment; Rep. Gr.94; Headlamp, Adjusting.

Wheel Bearing Housing Bonded Rubber Bushing, Replacing, AWD Vehicles

Special tools and workshop equipment required

- Bearing Installer - Control Arm -3346-

- Bearing Installer - Carrier Bearing -3350-

- Fitting Sleeve -3378-

- Torque Adapter -3390-

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Remove the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- Remove the brake caliper with the brake carrier and secure it to the body using wire. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Caliper, Removing and Installing.

Note

Note

Do not let the brake caliper hang on the brake hose - risk of damage.

- Remove the brake shield. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Shield, Removing and Installing.

- Remove the lower bolts -arrows- on vehicles with a Level Control System Sensor.

- Remove the nut -2- and remove the bolt -arrow- for the lower control arm -1-.

Pressing out bonded rubber bushing

- Install tools as shown in illustration.

1 - Bearing Installer - Control Arm - Nut -3346/3-

2 - Torque Adapter -3390-

3 - Bearing Installer - Carrier Bearing -3350-

4 - Nut, commercially available

5 - Bearing Installer - Control Arm - Spindle -3346/2-

- Remove bonded rubber bushing by turning spindle.

Installing the bonded rubber bushing

- Install tools as shown in illustration.

1 - Bearing Installer - Control Arm - Nut -3346/3-

2 - Bearing Installer - Control Arm -3346-

3 - Bonded rubber bushing

4 - Fitting Sleeve -3378-

5 - Nut, commercially available

6 - Bearing Installer - Control Arm - Spindle -3346/2-

- Install bonded rubber bushing by turning support arm bearing installation tool.

Note

Note

- Do not use lubricant!

- Insert bearing with care so it is not canted.

- Check the installed position after installing the bonded rubber bushing.

- Dimensions -A- and -B- must be the same (each measured, if applicable, at a spot where there is no seam/burr).

- Install the bonded rubber bushing again if dimensions -A- and -B- are different.

Use a commercially available 27 mm socket wrench in place of the Fitting Sleeve -3378- to install the bonded rubber bushing.

Installing

Installation is reverse of removal, noting the following:

Bolting at wheel bearing housing may only occur when the dimension between wheel hub center and lower edge of wheel housing, measured before assembly, is achieved. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Install the brake caliper. Refer to → Brake System; Rep. Gr.46; Rear Brakes; Brake Caliper, Removing and Installing.

- Install the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

- Perform the headlamp basic setting. Refer to Vehicle Diagnosis Tester.

- For vehicles with electronic damping, perform the basic setting using the Vehicle Diagnosis Tester.