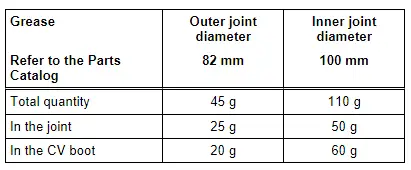

Audi Q3: Overview - Drive Axle

Overview - Drive Axle, Drive Axle with 100 mm Inner CV Joint

Note

Note

Grease joint again when replacing protective joint boot.

1 - Outer CV Joint

- Replace only as complete unit.

- When installing the joint on the profile shaft, the splines on the profile shaft must be lightly coated with grease used in joint.

- Checking. Refer to → Chapter "Outer CV Joint, Checking".

- Removing. Refer to → Fig. "Removing the outer CV joint".

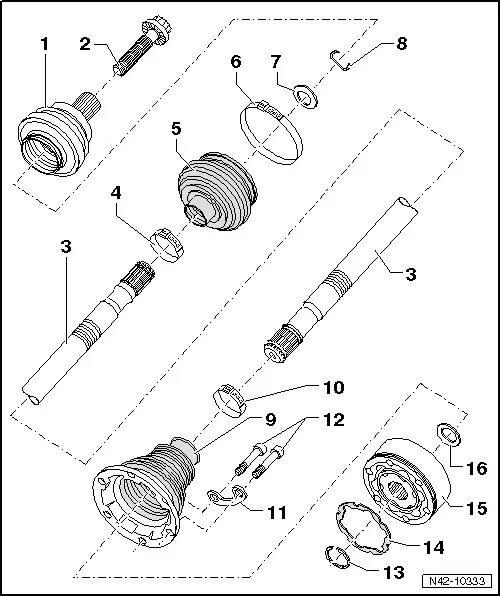

- Grease table.

- Installing.

2 - Bolt

- Twelve-point bolt tightening specification: 200 Nm + 180º additional turn

- Always replace if removed

- Before installing, clean the threads in the CV joint with a tap.

The vehicle must be on the ground when tightening.

- Loosening and tightening the twelve-point bolt. Refer to

3 - Profile Shaft

4 - Clamp

- Replace

- Tensioning. Refer to or → Fig. "Clamps for rubber protective joint boots, tensioning"

5 - CV Boot for Outer CV Joint

- Without vent hole

- Check for tears and scuffing

6 - Clamp

- Replace

- Tensioning. Refer to or → Fig. "Clamps for rubber protective joint boots, tensioning"

7 - Plate Spring

- Installed position.

8 - Spacer Ring (Plastic)

- Installed position.

9 - Locking Ring

- Replace

- Insert in shaft groove

10 - CV Boot for Inner CV Joint

- Without vent hole

- Check for tears and scuffing

- Drive off CV joint using drift

- Coat the sealing surface with D 454 300 A2 before installing it on the CV joint

11 - Clamp

- Replace

- Tensioning. Refer to or → Fig. "Clamps for rubber protective joint boots, tensioning"

12 - Locking Plate

13 - Internal multipoint Bolt

- First tighten diagonally to 10 Nm, then tighten diagonally again to the tightening specification.

- M8 tightening specification: diagonal sequence to 40 Nm

- M10 tightening specification: diagonal sequence to 70 Nm

- Always replace if removed

14 - Locking Ring

- Replace

- Remove and install using Circlip Pliers -VW161A-. Refer to → Fig. "Circlip, removing and installing".

15 - Seal

- Bonding surface on CV joint must be free of grease and oil!

16 - Inner CV Joint

- Replace only as complete unit.

- Grease table, page.

- Checking. Refer to → Chapter "Inner CV Joint, Checking".

- Removing.

- When installing the joint on the profile shaft, the splines on the profile shaft must be lightly coated with grease used in joint.

- Installing.

17 - Plate Spring

- Installed position.

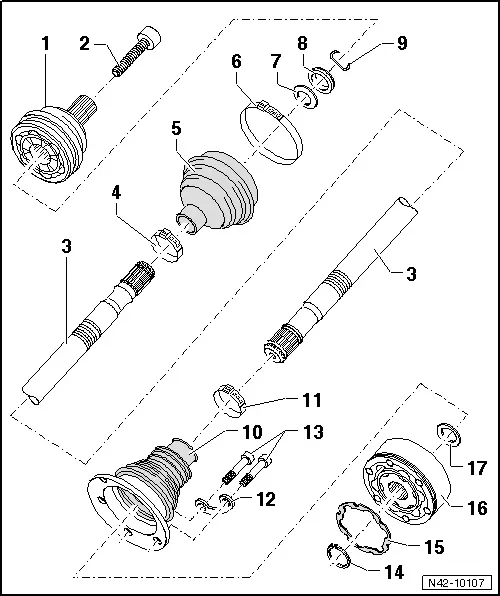

Overview - Drive Axle, Drive Axle with 82 mm Outer CV Joint

1 - Outer CV Joint

- Replace only as complete unit.

- Removing. Refer to → Fig. "Outer CV joint, pressing off".

- Installing: using a plastic mallet, drive onto the shaft as far as the stop

- Divide the grease evenly in the joint

- Checking. Refer to → Chapter "Outer CV Joint, Checking".

2 - Bolt

- Twelve-point bolt tightening specification: 200 Nm + 180º additional turn. Refer to → Chapter "Drive Axle Threaded Connection, Loosening and Tightening".

- Always replace if removed

- Before installing, clean the threads in the CV joint with a tap.

3 - Drive Axle

- For allocation. Refer to the Parts Catalog.

4 - Clamp

- Always replace if removed

- Tensioning.

5 - CV Boot

- Check for tears and scuffing

- Material: polyelastomer

6 - Clamp

- Always replace if removed

- Tensioning.

7 - Plate Spring

- With inner spline

- Installed position.

8 - Locking Ring

- Always replace if removed

- Insert in shaft groove

9 - CV Boot for CV joint

- Material: polyelastomer

- Without vent hole

- Check for tears and scuffing

- Drive off CV joint using drift

- Coat the sealing surface with -D 454 300 A2- before installing it on the CV joint

10 - Clamp

- Always replace if removed

- Tensioning.

11 - Locking Plate

12 - Internal multipoint Bolt

- M8 tightening specification: diagonal sequence to 40 Nm.

- M10 tightening specification: diagonal sequence to 70 Nm.

- Always replace if removed

- First tighten diagonally to 10 Nm, then tighten diagonally again to the tightening specification

13 - Locking Ring

- Always replace if removed

- Remove and install using Circlip Pliers -VW161A-.

14 - Seal

- Always replace if removed

- Bonding surface on CV joint must be free of grease and oil!

15 - Inner CV Joint

- Replace only as complete unit.

- Divide the grease evenly in the joint

- Removing. Refer to

- Installing. Refer to

- Checking. Refer to → Chapter "Inner CV Joint, Checking".

16 - Plate Spring

- With inner spline

- Installed position.

Filling Joints with Grease