Audi Q3: Vehicle Electrical System, General Repair Information

Audi Q3 (8U) 2011-2018 Service Manual / Electrical System / Electrical Equipment General Information / Wiring / Vehicle Electrical System, General Repair Information

Caution

Caution

When disconnecting and connecting battery, the procedure must be followed as described in the Repair Manual.

WARNING

WARNING

Some tools are supplied with a tool safety clip, which is slid over the tool points after using the tool, in order to protect other workers from injuries and tool points from damage.

- Observe the current notes in the corresponding repair manual for all repairs.

- Observe country-specific regulations.

- Before working on the electrical system, the battery Ground (GND) cable must be disconnected. By disconnecting the battery GND cable (current disruption), the electrical system is guaranteed to be safe to work on. Disconnecting the positive battery cable is only required when removing the battery.

- Before starting a repair, the cause of the damage must be eliminated first (for example sharp edges on chassis parts, faulty electrical consumers, corrosion etc.).

- For the wiring harnesses if possible a high quality replacement part is always delivered. This means that previously not required connector housings may be present on the replacement part.

- Additionally bend back the non-necessary connector housing when possible in a dry area of the vehicle and route them so that no noises can result.

- Additionally to prevent capillary action seal the non-necessary connector housing and single wires in wet areas of the vehicle with water tight heat-shrinkable tube. The necessary components to seal the single wires can be found in the Parts Catalog.

- Further information, for example, installing and removing the individual components, can be found in the appropriate Repair Manual.

- Soldering is not permissible for repairs to the vehicle electrical system.

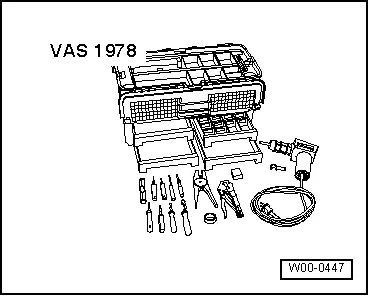

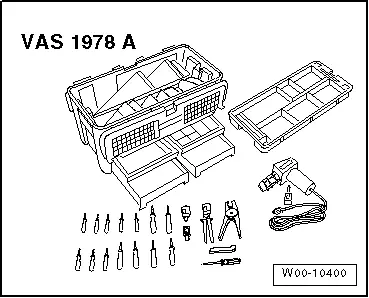

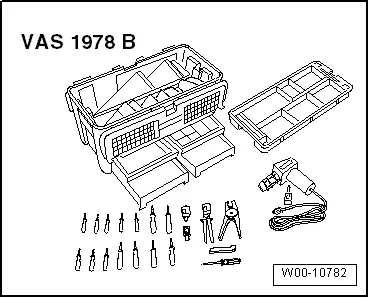

- Wiring harness and connector repairs on the vehicle electrical system may only be performed using Wiring Harness Repair Set -VAS1978B- and previous versions such as the Wiring Harness Repair Set -VAS631001- and the Wiring Harness Repair Set -VAS631003-. Only use the yellow wires from the corresponding wiring harness-repair kit.

- Wiring harness repairs may not be performed again in the wrapping of the vehicle-specific wiring harness and are to be marked with yellow adhesive tape. This indicated a previous repair.

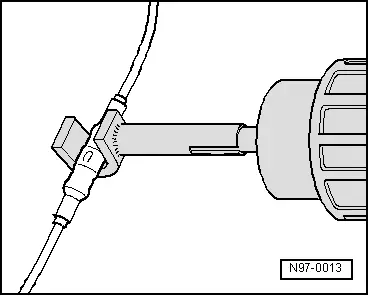

- Pinch and butt connectors must not be repaired. If necessary, lay a wire parallel to the faulty wire. After crimping, crimp connections must be heat-shrunk using hot air gun to prevent moisture penetration. Connectors with corresponding heat-shrinkable tube must be protected moisture penetration.

- Always observe the supplementary notes for repairing wiring harnesses on airbag- and seat belt tensioner systems, fiber optic cables, CAN bus lines, FlexRay wires, and antenna wires.

- A function test must be performed after every repair. If necessary, check Diagnostic Trouble Code (DTC) memory, erase and/or bring systems into basic setting.

- If possible, do not loosen grounding straps from the body (danger of corrosion).

- Not all wire cross-sections in the vehicle are contained in the Wiring Harness Repair Set -VAS1978B- and its previous versions. If the required wire cross-section is not present, the next greater cross-section must be used.

- Heat-resistant wires have been installed in the vehicle at various locations, mainly in the engine compartment. Heat-resistant wires can be recognized by their somewhat duller and softer insulation. Only heat-resistant wires may be used to repair these wires.

READ NEXT:

Wiring Harness Repair Set

Wiring Harness Repair Set

Wiring Harness Repair Set -VAS1978-

The Wiring Harness Repair Set -VAS1978- makes optimal repair

quality possible in the realm of vehicle electronics. Using the

tools, repairs affecting harness c

Tool Descriptions

Tool Descriptions

Crimping Pliers with Insert

The Crimping Pliers without Insert -VAS1978/1- with Crimping

Pliers - Insert 2 -VAS1978/2- is a component of the Wiring

Harness Repair Set -VAS1978- and is used to cri

Airbag and Belt Tensioner Wires, Repairing

Airbag and Belt Tensioner Wires, Repairing

In addition to the general repairs on wiring harnesses, the following methods

and instructions must be observed for repairs on airbag- and seat belt tensioner

wires:

WARNING

The air

SEE MORE:

Battery Tester -VAS6161- Device Description

Battery Tester -VAS6161- Device Description

Battery Tester -VAS6161-

1 - Internal printer

2 - Operating lever for the paper tray

3 - Paper slot

4 - Main menu display

5 - Display with on/off-button

6 - Connection for the battery tester cable

7 - Slot for the SD memory

Rear Window Wiper System

Rear Window Wiper System

Overview - Rear Window Washer System

1 - Water Hose

For the rear window washer system

2 - Nut

8 Nm

3 - Rear Window Wiper Motor -V12-

Removing and installing. Refer to

→ Chapter "Rear Window Wiper Motor -V12-, Removing and Installing".

4&

© 2019-2026 Copyright www.auq3.net