Audi Q3: Disposal

Front Shock Absorbers, Venting and Emptying

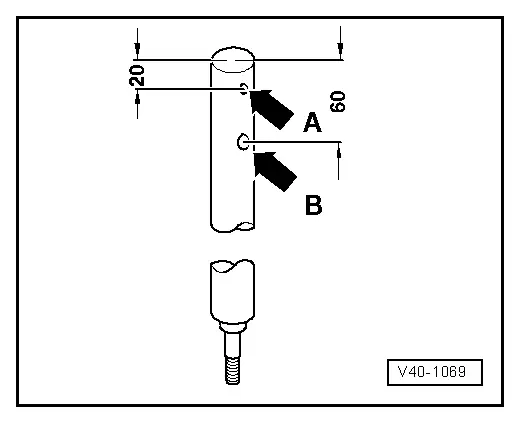

Method A - Venting through Drill Holes

- Secure gas-filled shock absorber vertically in vise, with piston rod facing down.

WARNING

WARNING

Wear protective eyewear while drilling.

Note

Note

Gas escapes when drilling.

- Drill a 3 mm (0.12 in) hole -arrow A- through the shock absorber outer tube.

- Continue drilling until the tube inside is drilled through, approximately 25 mm (1 in) deep.

- Drill a second 6 mm (0.24 in) hole -arrow B- through the outer and inner shock absorber tubes.

- Hold shock absorber over appropriate container for catching oil and move piston rod repeatedly through entire stroke until no more oil flows out.

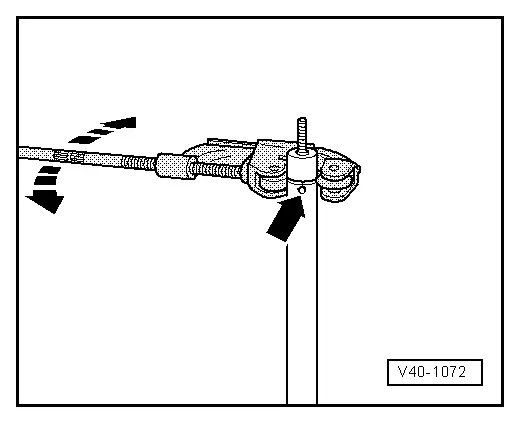

Method B - Open with Pipe Cutter

WARNING

WARNING

Wear protective eyewear when drilling or sawing.

Note

Note

Gas escapes when drilling or sawing.

- Drill a 3 mm (0.12 in) hole -arrow- through the shock absorber outer tube or saw through the tube wall.

- Attach a pipe cutter (for example a 150/3 Stahlwille Express) as shown in illustration, and cut through outer shock absorber tube.

- Pull the piston rod upward, hold the inner shock absorber tube in place with pliers and push it downward so that it remains in the outer shock absorber tube when the piston rod is slowly raised.

- Remove the piston rod from the shock absorber inner tube.

- Empty the shock absorber tube.

Rear Shock Absorbers, Venting and Emptying

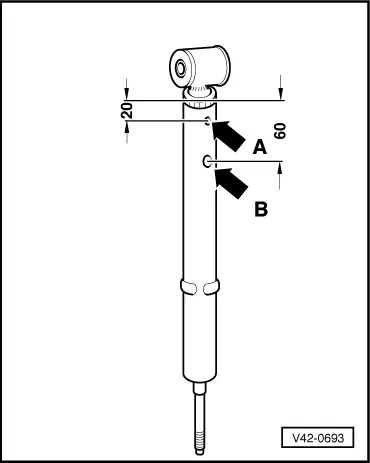

Method A - Venting through Drill Holes

- Secure gas-filled shock absorber vertically in vise, with piston rod facing down.

WARNING

WARNING

Wear protective eyewear while drilling.

- Drill a 3 mm (0.12 in) hole -arrow A- through the shock absorber outer tube.

Note

Note

Gas escapes when drilling.

- Continue drilling until the tube inside is drilled through, approximately 25 mm (1 in) deep.

- Drill a second 6 mm (0.24 in) hole -arrow B- through the outer and inner shock absorber tubes.

- Hold shock absorber over appropriate container for catching oil and move piston rod repeatedly through entire stroke until no more oil flows out.

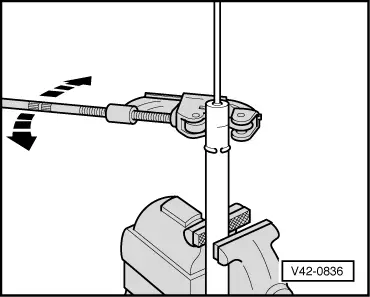

Method B - Open with Pipe Cutter

WARNING

WARNING

Wear protective eyewear when drilling or sawing.

- Drill a 3 mm (0.12 in) hole diameter through the shock absorber outer tube or saw through the tube wall.

Note

Note

Gas escapes when drilling or sawing.

- Attach a pipe cutter (for example a 150/3 Stahlwille Express) as shown in illustration, and cut through outer shock absorber tube.

- Pull the piston rod upward, hold the inner shock absorber tube in place with pliers and push it downward so that it remains in the outer shock absorber tube when the piston rod is slowly raised.

- Remove the piston rod from the shock absorber inner tube.

- Empty the shock absorber tube.

Special Tools

Special tools and workshop equipment required

- Tensioning Strap -T10038-

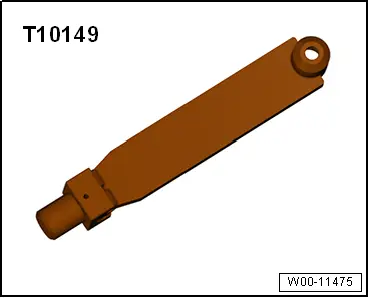

- Engine/Gearbox Jack Adapter - Wheel Hub Support -T10149-

- Maha Shock Absorber Tester -VAS1990- or

- Suspension Strut Test Bed -VAS6636- or

- Suspension Strut Test Bed VAS6640 -VAS6640-

- Engine and Gearbox Jack -VAS6931-