Audi Q3: 0.22 mm 2 Wire, Repairing with Individual Crimp Connector

Procedure

- Free up the wire to be repaired approximately 20 cm on both sides of the repair point.

Caution

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses carefully.

- If necessary, removing the wiring harness wrapping using a knife.

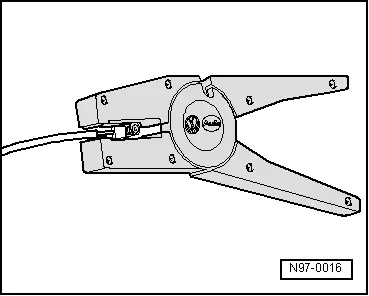

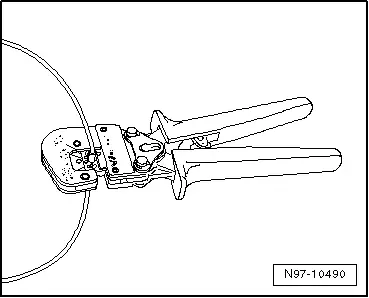

- Cut out the damaged section of wire using the Wiring Harness Repair Set - Wire Strippers -VAS1978/3-.

Note

Note

If, by cutting out the damaged wire section, both ends of the vehicle-specific single wire are too short for a repair using a single crimp connector, insert a repair wire section of matching length with two crimp connections. Refer to → Chapter "Repairing a 0.22 mm 2 Wire with Intermediate Wire Section".

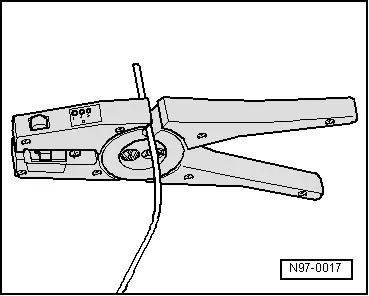

- Adjust the sliding stop in the Wiring Harness Repair Set - Wire Strippers -VAS1978/3- pliers jaws to 12 to 14 mm for the wire to be stripped.

- Insert wire end from front up to stop into jaws of pliers and squeeze the pliers completely.

- Open pliers again and remove the stripped wire end.

- Twist bare strands one-half turn.

- For the repair of a 0.22 mm 2 wire, use a small transparent crimp connector from the Wiring Harness Repair Set -VAS1978B-.

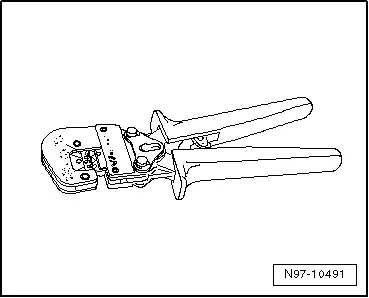

- To press the crimp connector, use the Wiring Harness Repair - Crimping Plier - Base Tool -VAS1978/1-2- with Wiring Harness Repair - Crimping Head - .35-2.5mm -VAS1978/1-1-.

- Slide the small transparent crimp connector onto both stripped, non-insulated wire ends on the vehicle-specific single wire and crimp them using crimp pliers.

Note

Note

Do not crimp wire insulation.

After crimping, crimp connections must be heat-shrunk using hot air gun to prevent moisture penetration.

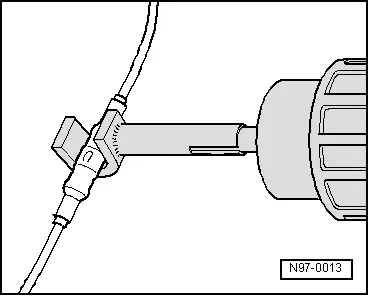

- Insert the Wiring Harness Repair - Blower - Shrink Element -VAS1978/15A- on the Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A-.

Caution

Caution

Risk of damaging surrounding components.

- When heat-shrinking crimp connections, be careful not to damage any other wiring, plastic parts or insulating material with the hot nozzle of the hot air blower.

- Always observe operating instructions of heat gun.

- Heat crimp connection using the hot air blower lengthwise from center outward until it is sealed completely and adhesive comes out the ends.

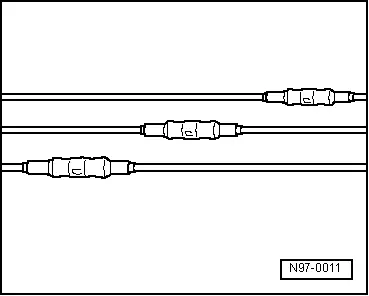

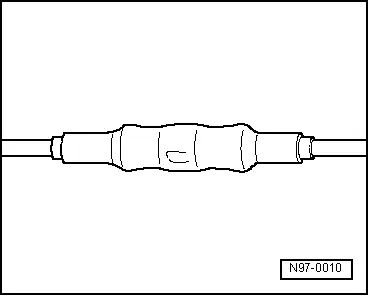

- This is how the completed repair location with individual crimp connector should appear.

Note

Note

- Make sure that crimp connections do not lie directly next to each other when several wires need to be repaired. Arrange the crimp connectors at a slight offset so that the circumference of the wiring harness does not become too large.

- If the repair point was previous taped, this point must be taped again with yellow insulating tape after repairs.

- Secure the repaired wiring harness if necessary with a cable tie to prevent flapping noises while driving.