Audi Q3: Tie Rod, Removing and Installing

Tie Rod, Removing and Installing, FWD Vehicles

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Remove the affected rear wheel. Refer to → Chapter "Wheels and Tires".

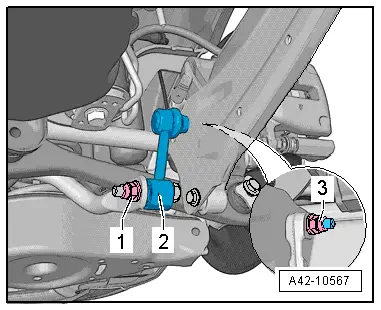

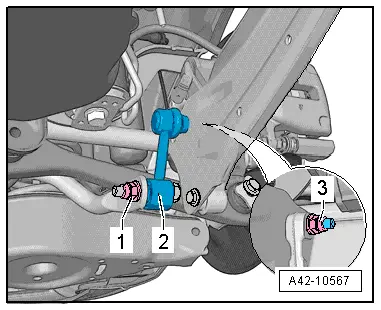

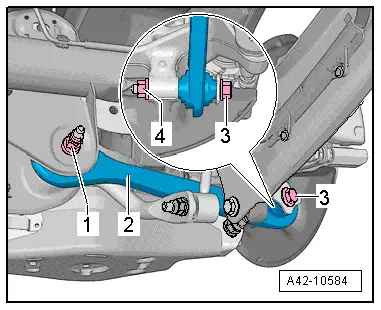

- Remove the nut -1- and pull the coupling rod -2- out of the stabilizer bar.

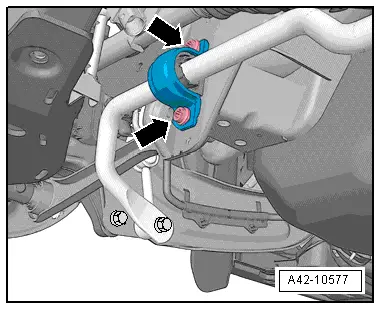

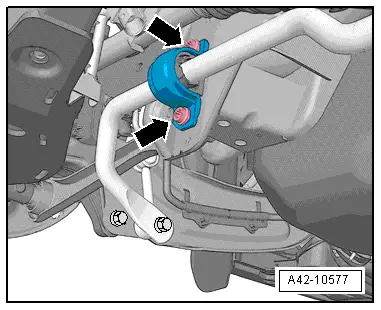

- Remove the bolts -arrows- for the stabilizer bar clamp. Refer to → Chapter "Stabilizer Bar, Removing and Installing".

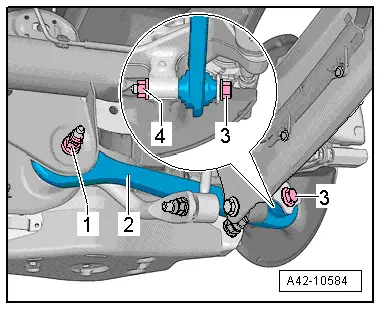

- Remove the nut -4- and bolt -3-.

- Remove the nut -1- and then remove the bolt to the rear.

- Remove the tie rod -2-.

Installing

Installation is reverse of removal, noting the following:

- The tie rod may only be fastened when the dimension between wheel hub center and lower edge of wheel housing, measured before assembly, is achieved. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

Tie Rod, Removing and Installing, AWD Vehicles

Special tools and workshop equipment required

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Remove the affected rear wheel. Refer to → Chapter "Wheels and Tires".

- Remove the nut -1- and pull the coupling rod -2- out of the stabilizer bar.

- Remove the bolts -arrows- for the stabilizer bar clamp.

- Remove the nut -4- and bolt -3-.

- Remove the nut -1- and then remove the bolt to the rear.

- Remove the bolt -2-.

Installing

Installation is reverse of removal, noting the following:

- The control arm may only be fastened if the dimension between the wheel hub center and lower edge of wheel housing, measured before assembly, is achieved. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Install the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".