Audi Q3: Rear Brake Caliper

Overview - Rear Brake Caliper

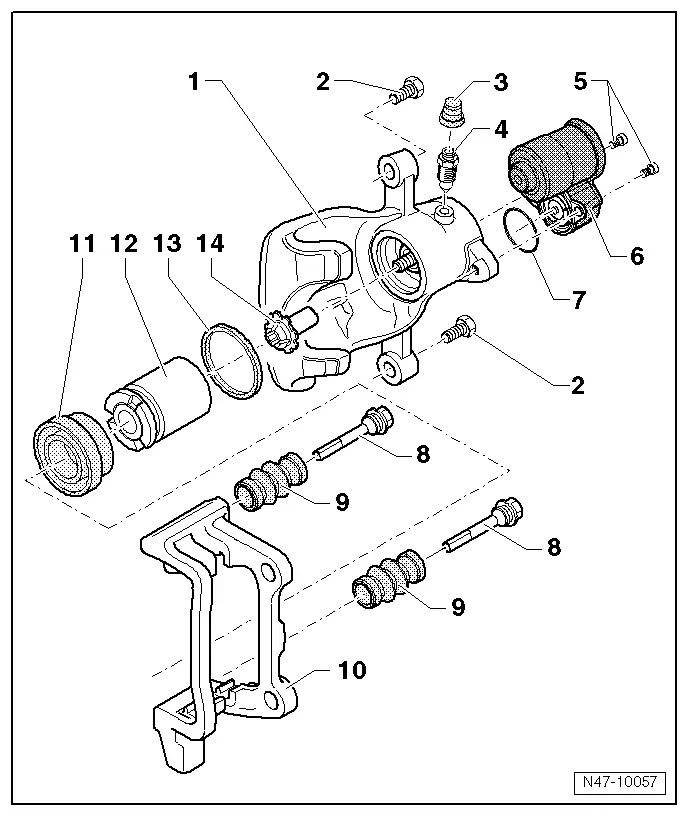

1 - Brake Caliper

- Pre-bleed brake caliper after repairing, refer to → Chapter "Hydraulic System, Pre-Bleeding".

2 - Bolt

- 35 Nm

- Replacing

- Self-locking

- When loosening and tightening, counter-hold at guide pin

3 - Dust Cap

4 - Bleeder Screw

- 13 Nm

- Before installing, lightly grease the thread with Lithium Grease -G 052 150 A2-.

5 - Bolt

- Tightening specification, refer to item -14-.

6 - Parking Brake Motor

7 - Seal

8 - Guide Pin

- Grease before pulling on protective cap

9 - Protective Cap

- Install on brake carrier and guide pin.

10 - Brake Carrier with Guide Pins and Cap

- Supplied as an assembled replacement part with sufficient grease on guide pins.

- Install the repair kit if the caps or guide pins are damaged. Use supplied grease packet to lubricate guide pins.

11 - Protective Cap

- Pull onto piston with outer sealing lip

- Removing and installing, refer to → Chapter "Brake Caliper Piston, Removing and Installing".

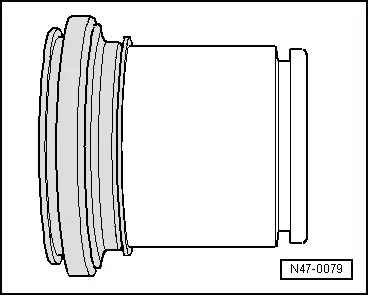

12 - Piston

- Removing and installing, refer to → Chapter "Brake Caliper Piston, Removing and Installing".

- Thinly coat the piston with Lithium Grease -G 052 150 A2-

13 - Seal

- Do not damage when installing piston

- Removing and installing, refer to → Chapter "Brake Caliper Piston, Removing and Installing".

14 - Pressure Nut

Brake Caliper Piston, Removing and Installing

Special tools and workshop equipment required

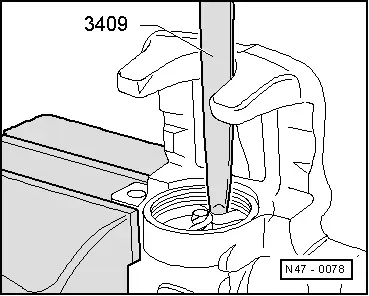

- Trim Removal Wedge -3409-

Removing

- The brake caliper is removed, refer to → Chapter "Brake Caliper, Replacing".

- The parking brake motor is removed, refer to → Chapter "Left/Right Parking Brake Motor -V282-/-V283-, Removing and Installing".

Note

Note

- Install complete repair kit when servicing.

- To clean the brakes only use mineral spirits.

- Thinly coat the brake cylinder, piston and seal with Lithium Grease -G 052 150 A2-.

- In case of repair, brake calipers must always be pre-bled before being installed into vehicle (without brake pads), refer to → Chapter "Hydraulic System, Pre-Bleeding".

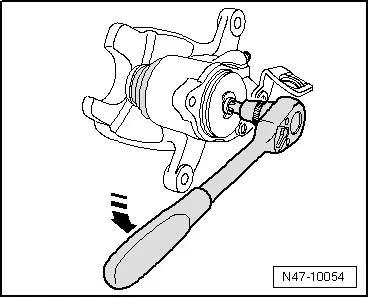

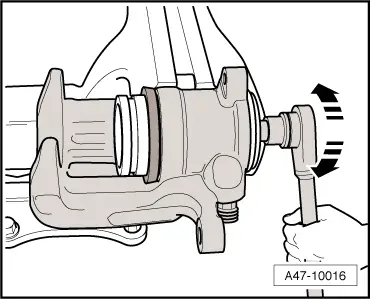

- Using an 8 mm internal multi-point socket, turn the spindle counter-clockwise in direction of -arrow-. As a result, the thrust nut pushes the piston out of the brake caliper.

- Remove the piston with the protective cap from the brake caliper.

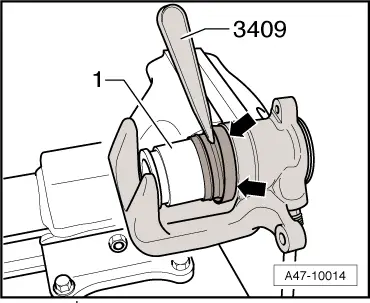

- Remove the sealing ring using the Trim Removal Wedge -3409-.

- Clean the surfaces on the pistons and seal only with mineral spirits and then dry.

Installing

- Thinly coat the piston and the seal with Lithium Grease -G 052 150 A2- before installing.

- Insert oil seal into brake caliper.

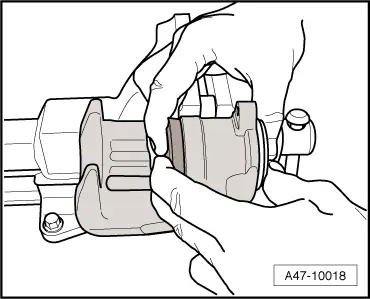

- Place protective cap with outer sealing lip on piston.

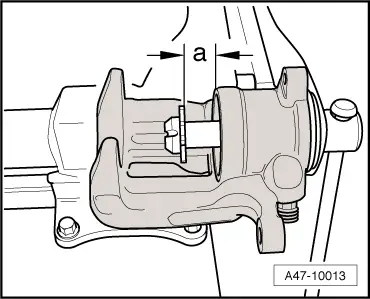

- Turn the thrust nut far enough onto the spindle so that the dimension -a- = 15 mm is reached.

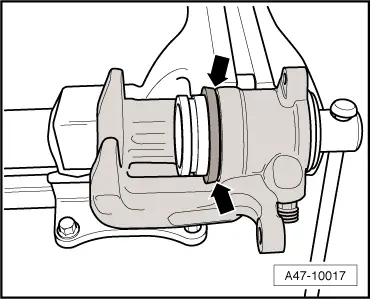

- Insert the inner sealing lip of the protective cap into the groove -arrows- in the brake caliper using the Trim Removal Wedge -3409-.

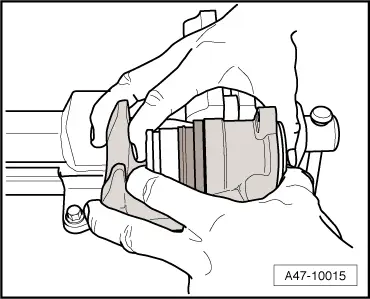

- Slide the piston onto the thrust nut, which is only possible in four positions.

- Carefully press the piston into the brake caliper by moving the piston.

- Press the piston far enough into the brake caliper until it touches the thrust nut.

- Carefully turn the spindle clockwise in direction of -arrows- until the thrust nut is at the stop.

- The protective cap must contact the brake caliper -arrows- all the way around.

- Press the piston into the brake caliper by hand

- Outer sealing lip of protective cap will then engage in piston groove.