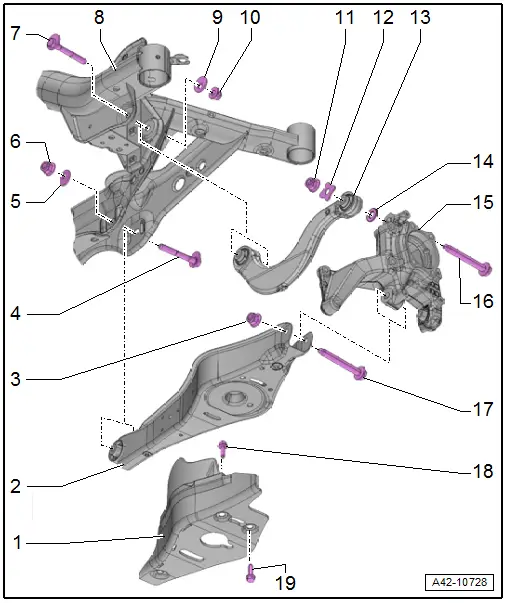

Audi Q3: Overview - Transverse Link

Audi Q3 (8U) 2011-2018 Service Manual / Chassis / Suspension, Wheels, Steering / Rear Suspension / Overview - Transverse Link

1 - Stone Chip Protection

- For allocation. Refer to the Parts Catalog.

2 - Lower Transverse Link

- Removing and installing. Refer to → Chapter "Lower Transverse Link, Removing and Installing, FWD Vehicles".

3 - Nut

- 90 Nm + 90º

- Always replace if removed

- Always tighten threaded connections in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

4 - Eccentric Screw

- Do not turn more than 90º right or left (that is smallest to largest possible adjustment)

- For toe setting

- Perform a vehicle alignment after loosening. Refer to → Chapter "Axle Alignment Procedure".

5 - Eccentric Washer

- Inner bore with tab

6 - Nut

- 95 Nm

- Always replace if removed

- Always tighten threaded connections in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

7 - Eccentric Screw

- Do not turn more than 90º right or left (that is smallest to largest possible adjustment)

- For camber setting

- Perform a vehicle alignment after loosening. Refer to → Chapter "Axle Alignment Procedure".

8 - Subframe

- Removing and installing. Refer to → Chapter "Subframe, Removing and installing, FWD Vehicles".

9 - Eccentric Washer

- Inner bore with tab

10 - Nut

- 95 Nm

- 80 Nm. This tightening specification only applies in conjunction with Insert Tool - 18mm -T10179-

- Always replace if removed

- Always tighten threaded connections in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

11 - Nut

- For tightening specifications, see bolt -16-

- Always replace if removed

12 - Washer

13 - Upper Transverse Link

- Removing and installing. Refer to → Chapter "Upper Transverse Link, Removing and Installing, FWD Vehicles".

14 - Washer

15 - Wheel Bearing Housing

16 - Bolt

- 130 Nm + 90º

- Always replace if removed

- Always tighten threaded connections in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

17 - Bolt

- Always replace if removed

18 - Expanding Rivet

- Quantity: 2

19 - Bolt

- 8 Nm

- Quantity: 3

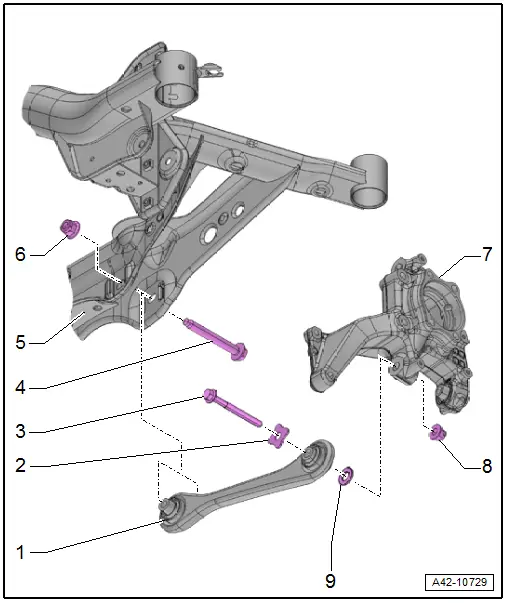

Overview - Tie Rod

1 - Tie Rod

- Removing and installing. Refer to → Chapter "Tie Rod, Removing and Installing, FWD Vehicles".

2 - Washer

3 - Bolt

- 130 Nm + 90º

- Always replace if removed

- Always tighten threaded connections in curb weight position. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

4 - Bolt

- Always replace if removed

5 - Subframe

- Removing and installing. Refer to → Chapter "Subframe, Removing and installing, FWD Vehicles".

6 - Nut

- 90 Nm + 90º

- Always replace if removed

7 - Wheel Bearing Housing

8 - Nut

- Always replace if removed

9 - Washer

READ NEXT:

Upper Transverse Link, Removing and Installing

Upper Transverse Link, Removing and Installing

Upper Transverse Link, Removing and Installing, FWD Vehicles

Special tools and workshop equipment

required

Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from cente

Lower Transverse Link, Removing and Installing

Lower Transverse Link, Removing and Installing

Lower Transverse Link, Removing and Installing, FWD Vehicles

Special tools and workshop equipment

required

Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from cente

Tie Rod, Removing and Installing

Tie Rod, Removing and Installing

Tie Rod, Removing and Installing, FWD Vehicles

Special tools and workshop equipment

required

Torque Wrench 1331 5-50Nm -VAG1331-

Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Meas

SEE MORE:

Passenger Compartment Forced Air Extraction, Checking

Passenger Compartment Forced Air Extraction, Checking

Ventilation Slots in Luggage Compartment, Checking

Test Sequence

- Check the left and right air guides through the vent

openings -arrow- built into the

luggage compartment side trim panel -1-.

Note

Closed or blocked air ducts to the forced air extraction

vent frames can cause

Technical data

Technical data

Identification data

Vehicle data label

Fig. 176 Vehicle identification label

The vehicle identification label

fig. 176 is located

in the luggage compartment under the cargo

floor cover.

The sticker contains the following vehicle data:

Vehicle Identification Number (VIN)

Vehicle type, displace

© 2019-2026 Copyright www.auq3.net