Audi Q3: Lower Transverse Link, Removing and Installing

Lower Transverse Link, Removing and Installing, FWD Vehicles

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Remove the coil spring. Refer to → Chapter "Spring, Removing and Installing".

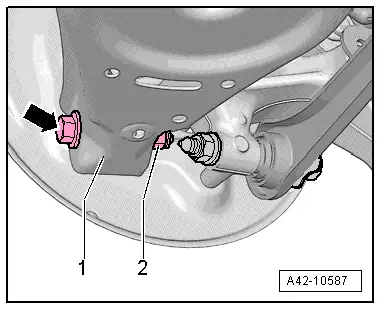

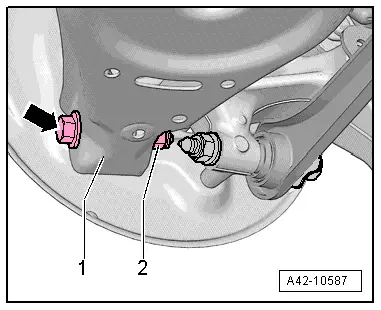

- Remove the nut -2- and remove the bolt -arrow- for the lower control arm -1-.

Vehicles with Left Rear Level Control System Sensor -G76-/Right Rear Level Control System Sensor -G77-

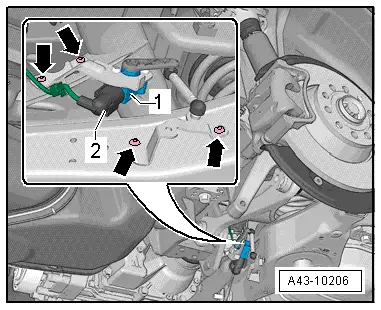

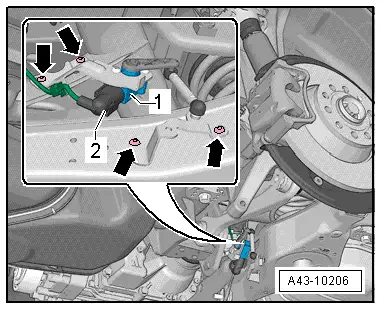

- Remove the bolts -lower arrows-.

Continuation for all vehicles

- For removing the left control arm, disengage and lower the exhaust system rear section. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

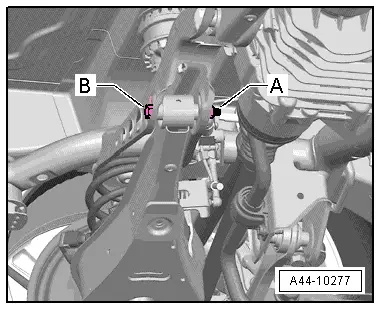

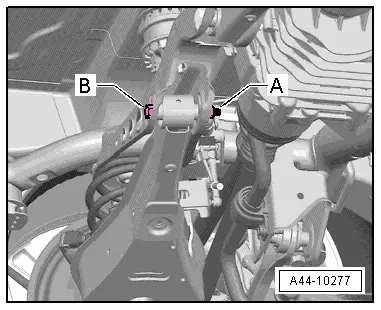

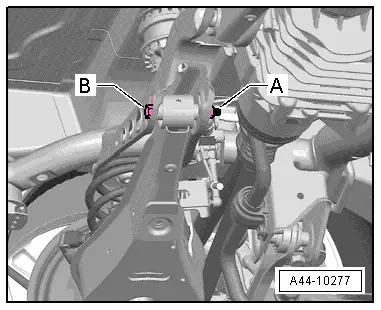

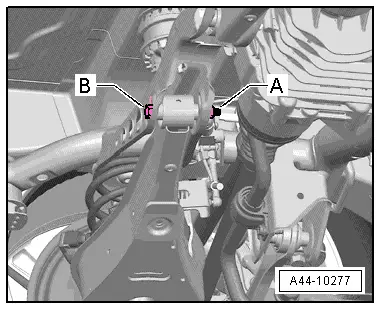

- Mark the position of eccentric screw -B- to the subframe using, for example, a felt-tip marker.

- Remove the nut -A- and the eccentric screw -B-.

- Remove the lower control arm.

Installing

Installation is reverse of removal, noting the following:

- The control arm may only be fastened if the dimension between the wheel hub center and lower edge of wheel housing, measured before assembly, is achieved. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Note the applied marking of the eccentric screw -B- to the subframe.

- Install the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

- On vehicles with electronically controlled damping, perform the function "Adapt the control position" with the Vehicle Diagnosis Tester.

- If the control position was reprogrammed and if the vehicle has lane assist, then it will then be necessary to calibrate the driver assistance systems front camera. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".

- On vehicles with level control system sensor, perform headlamp basic setting. Refer to → Electrical Equipment; Rep. Gr.94; Headlamp, Adjusting.

Lower Transverse Link, Removing and Installing, AWD Vehicles

Special tools and workshop equipment required

- Torque Wrench 1332 40-200Nm -VAG1332-

Removing

- Measure dimension from center of wheel to lower edge of wheel housing. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Remove the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- Remove the nut -2- and remove the bolt -arrow- for the lower control arm -1-.

Vehicles with Left Rear Level Control System Sensor -G76-/Right Rear Level Control System Sensor -G77-

- Remove the bolts -lower arrows-.

Continuation for all vehicles

- For removing the left control arm, disengage and lower the exhaust system rear section. Refer to → Rep. Gr.26; Exhaust Pipes/Mufflers; Overview - Muffler.

- Mark the position of eccentric screw -B- to the subframe using, for example, a felt-tip marker.

- Remove the nut -A- and the bolt -B-.

- Remove the lower control arm.

Installing

Installation is reverse of removal, noting the following:

- The control arm may only be fastened if the dimension between the wheel hub center and lower edge of wheel housing, measured before assembly, is achieved. Refer to → Chapter "Wheel Bearing in Curb Weight, Lifting Vehicles with Coil Spring".

- Observe the applied marking for the eccentric screw -arrow B- to the subframe.

- Install the coil spring. Refer to → Chapter "Spring, Removing and Installing".

- An axle alignment may be required. Refer to → Chapter "Evaluating Need for Axle Alignment".

- On vehicles with electronically controlled damping, perform the function "Adapt the control position" with the Vehicle Diagnosis Tester.

- If the control position was reprogrammed and if the vehicle has lane assist, then it will then be necessary to calibrate the driver assistance systems front camera. Refer to → Chapter "Driver Assistance Systems Front Camera, Calibrating".

- On vehicles with level control system sensor, perform headlamp basic setting. Refer to → Electrical Equipment; Rep. Gr.94; Headlamp, Adjusting.