Audi Q3: Overview - Subframe

Audi Q3 (8U) 2011-2018 Service Manual / Chassis / Suspension, Wheels, Steering / Rear Suspension / Overview - Subframe

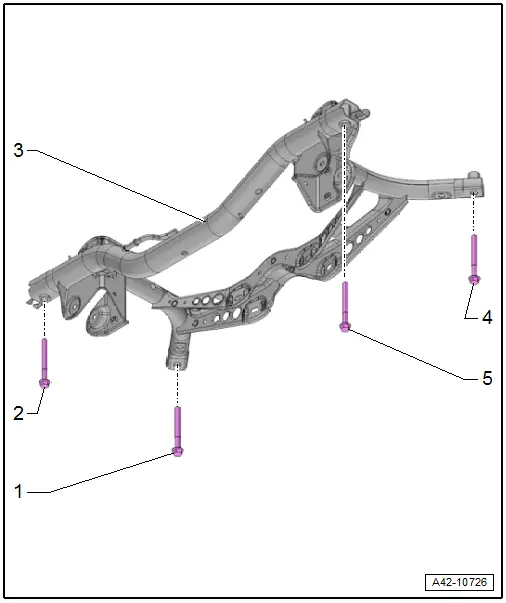

Overview - Subframe, Vehicles with FWD

Caution

Caution

There is a risk of damaging the subframe threaded connection threads on the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

1 - Bolt

- 90 Nm + 90º

- Always replace if removed

2 - Subframe

- Removing and installing. Refer to → Chapter "Subframe, Removing and installing, FWD Vehicles".

3 - Bolt

- 90 Nm + 90º

- Always replace if removed

4 - Bolt

- 90 Nm + 90º

- Always replace if removed

5 - Bolt

- 90 Nm + 90º

- Always replace if removed

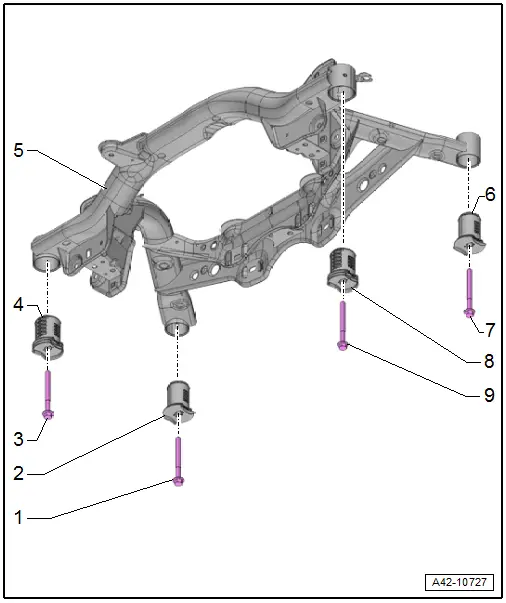

Overview - Subframe, Vehicles with AWD

Caution

Caution

There is a risk of damaging the subframe threaded connection threads on the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

1 - Bolt

- 90 Nm +90º

- Always replace if removed

2 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Subframe, Servicing".

3 - Bolt

- 90 Nm +90º

- Always replace if removed

4 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Subframe, Servicing".

5 - Subframe

- Removing and installing. Refer to → Chapter "Subframe, Removing and Installing, AWD Vehicles".

- 6 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Subframe, Servicing".

7 - Bolt

- 90 Nm +90º

- Always replace if removed

8 - Bonded Rubber Bushing

- Replacing. Refer to → Chapter "Subframe, Servicing".

9 - Bolt

- 90 Nm +90º

- Always replace if removed

READ NEXT:

Subframe, Removing and Installing

Subframe, Removing and Installing

Subframe, Removing and installing, FWD Vehicles

Special tools and workshop equipment

required

Locating Pins -T10096-

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Subframe, Servicing

Subframe, Servicing

Tools and Preliminary Work

Special tools and workshop equipment

required

Hydraulic Press -VAS6178-

with Bearing Installer - Wheel Hub/Bearing Kit - Pressure

Head -T10205/13- from the Bearin

Stabilizer Bar

Stabilizer Bar

Overview - Stabilizer Bar

1 - Subframe

2 - Bolt

25 Nm + 45º

Always replace if removed

Install evenly

3 - Clamp

4 - Bearing

Always replace t

SEE MORE:

Tires with Emergency Running Characteristics, SST (Self-Supporting Tire)

Tires with Emergency Running Characteristics, SST (Self-Supporting Tire)

Caution

It is mandatory for run-flat tires to have a tire

pressure monitoring system in the vehicle.

Note

Only vehicles with a tire pressure monitoring system are

equipped with SST tires. This warns the driver when tire

pressure falls below a certain value.

Tire dama

Component Location Overview - Airbag Crash Sensors

Component Location Overview - Airbag Crash Sensors

Component Location Overview - Airbag Crash Sensors, USA and Canada

Market-Specific

1 - Passenger Side Front Airbag Crash Sensor -G284-

Component location: on the right of the lock carrier

Removing and installing. Refer to

→ Chapter "Drive/Front Passenger Front Airbag Cr

© 2019-2026 Copyright www.auq3.net