Audi Q3: Overview - Subframe

Audi Q3 (8U) 2011-2018 Service Manual / Chassis / Suspension, Wheels, Steering / Front Suspension / Overview - Subframe

Caution

Caution

There is a risk of damaging the subframe threaded connection threads on the body.

- The subframe bolts on the body must not be loosened or tightened with an impact wrench.

- Always install all bolts by hand for the first few turns.

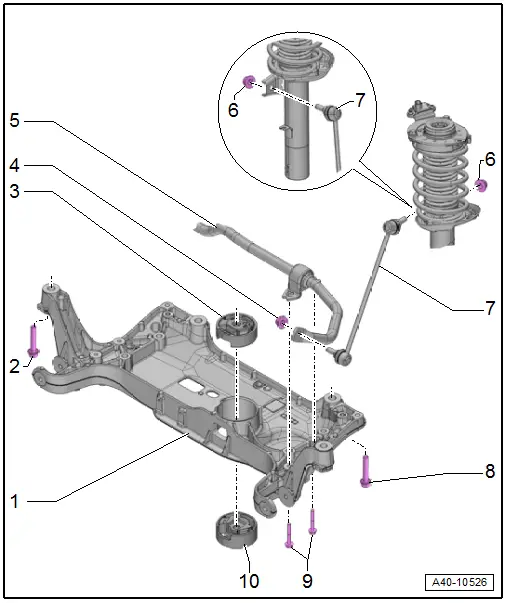

1 - Subframe

- Securing. Refer to → Chapter "Subframe, Securing".

- Lowering. Refer to → Chapter "Subframe, Lowering".

- Removing and installing without steering gear. Refer to → Chapter "Subframe without Steering Gear, Removing and Installing".

- Removing and installing with steering gear. Refer to → Chapter "Subframe with Steering Gear, Removing and Installing".

2 - Bolt

- 70 Nm +180º

- Always replace if removed

3 - Upper Bonded Rubber Bushing for Pendulum Support

- Replacing. Refer to → Chapter "Subframe, Servicing".

4 - Nut

- 65 Nm

- Always replace if removed

- Counterhold at socket head of joint bolt when tightening

5 - Stabilizer Bar

- Removing and installing. Refer to → Chapter "Stabilizer Bar, Removing and Installing".

6 - Nut

- 65 Nm

- Always replace if removed

- Counterhold at socket head of joint bolt when tightening

7 - Coupling Rod

- Removing and installing. Refer to → Chapter "Coupling Rod, Removing and Installing".

8 - Bolt

- 70 Nm +180º

- Always replace if removed

9 - Bolts

- 20 Nm +90º

- Always replace if removed

10 - Lower Bonded Rubber Bushing for Pendulum Support

- Replacing. Refer to → Chapter "Subframe, Servicing".

READ NEXT:

Subframe without Steering Gear, Removing and Installing

Subframe without Steering Gear, Removing and Installing

Special tools and workshop equipment

required

Torque Wrench 1331 5-50Nm -VAG1331-

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Removing

Note

Subframe

Subframe, Servicing

Subframe, Servicing

Special tools and workshop equipment

required

Bearing Installer - Wheel Hub/Bearing Kit -T10205-

Torque Wrench 1332 40-200Nm -VAG1332-

Hydraulic Press -VAS6178-

Pneumatic/Hydraulic Foot Pu

Stabilizer Bar, Removing and Installing

Stabilizer Bar, Removing and Installing

Special tools and workshop equipment

required

Locating Pins -T10096-

Torque Wrench 1332 40-200Nm -VAG1332-

Engine and Gearbox Jack -VAS6931-

Puller - Ball Joint -3287A-

Removing

-

SEE MORE:

Introduction

Introduction

The purpose of this repair manual is to provide service

advisors and technicians with the basic knowledge needed to

ensure professional and competent procedures.

Note

Only the careful study of this documentation, practical

implementation of the information contained, training on A/C

Passenger Occupant Detection System

Passenger Occupant Detection System

Component Location Overview - Passenger Occupant Detection System

WARNING

The replacement part (service kit) for the passenger

occupant detection system is already precalibrated and must not

be separated under any circumstances. The service kit consists

of:

Passenger Occupant D

© 2019-2026 Copyright www.auq3.net