Audi Q3: Airbag and Belt Tensioner Wires, Repairing

Audi Q3 (8U) 2011-2018 Service Manual / Electrical System / Electrical Equipment General Information / Wiring / Airbag and Belt Tensioner Wires, Repairing

In addition to the general repairs on wiring harnesses, the following methods and instructions must be observed for repairs on airbag- and seat belt tensioner wires:

WARNING

WARNING

- The airbag and seat belt tensioner system can fail.

- Faulty repairs performed on airbag and seat belt tensioner system can lead to malfunction in passenger protection.

- When performing repairs on airbag and seat belt tensioner wiring harness, use only terminals, connectors and wires designated for it. Refer to the Parts Catalog.

Note

Note

- Air bag wires and the safety belt tensioner wiring harness may repaired only with the Wiring Harness Repair Set -VAS1978B- and previous versions.

- Observe general notes for repairs on the vehicle electrical system. Refer to → Chapter "Vehicle Electrical System, General Repair Information".

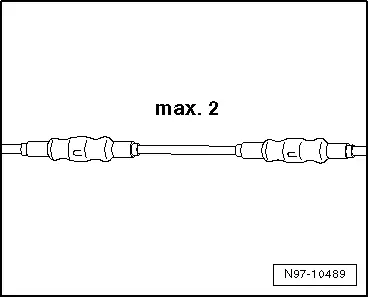

- A maximum of two repairs may be performed when repairing wires of airbag- and seat belt tensioner system. Repairs increase the electrical resistance in the wire and may trigger malfunctions in the system On Board Diagnostic (OBD).

- When repairing wiring harness of airbag- and seat belt tensioner system, the crimp connectors must always be heat-shrunk to prevent corrosion.

- Do not wrap the repair point again into the vehicle-specific wiring harness and mark the repair point quite visibly with yellow insulating tape.

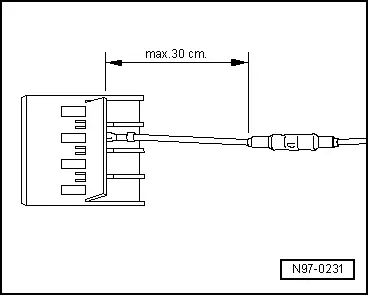

- Repairs in the area of the airbag or seat belt tensioner should be performed a maximum of 30 cm from the next connector housing. Together with the identification via yellow insulating tape, this procedure makes it possible to obtain a quick overview of previously performed repairs.

- Wires to the deploying units (airbags) have a wire-twisting with a length of lay of 20 mm +- 5 mm in series production. This length of lay is guaranteed via the norm part numbers for wire pairs in series production and must be observed strictly for the repair lengths of twisted wires.

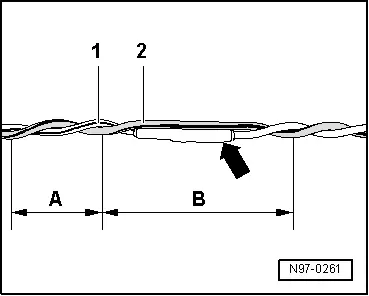

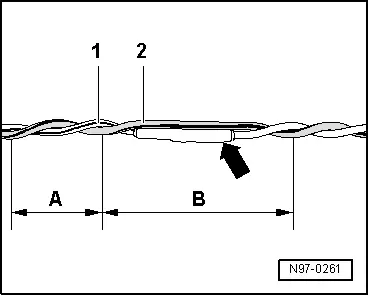

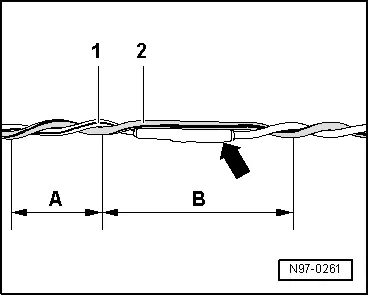

- During repair work, wires to deploying units (airbags) must have the same length. When twisting together wires -1 and 2-, length of lay of A = 20 mm +- 5 must be strictly observed.

- While doing this, no section of the wire, for example, in area of crimp connectors -arrow-, may be greater than B = 100 mm without twisting of the wires.

- Repairs are to be documented in the Audi Service Plan under "Space for workshop entries" with a short commentary of scope of repairs, workshop stamp and signature.

- Any warranty claims to Audi AG are void for repairs on airbag wiring set which were not performed using original replacement parts and Wiring Harness Repair Set -VAS1978-.

Repairing CAN bus Wires

- Unshielded, twisted two-wire lines -1 and 2- with a cross section of 0.35 mm 2 or 0.5 mm2 can be used as CAN-Bus wiring.

- Repairs on CAN-Bus wires can be performed with repair wire with matching cross section and also with twisted wires "green/yellow" or "white/yellow" from the Parts Catalog.

- When repairing CAN bus wires, both wires must be same length. When twisting together wires -1 and 2-, the lay length of A = 20 mm must be observed.

- While doing this, no section of the wire, for example, in area of crimp connectors -arrow-, may be greater than B = 50 mm without twisting of the wires.

- Wrap repair points with yellow adhesive tape to mark a performed repair.

Repair Kit for FlexRay Wires with Coating

Note

Note

- The repair of FlexRay wires with coating can only take place using FlexRay wires with coating from the Parts Catalog.

- Observe general notes for repairs on the vehicle electrical system. Refer to → Chapter "Vehicle Electrical System, General Repair Information".

A two-layer wire -1 and 2- with a 0.35 mm 2 profile is used as a FlexRay wire.

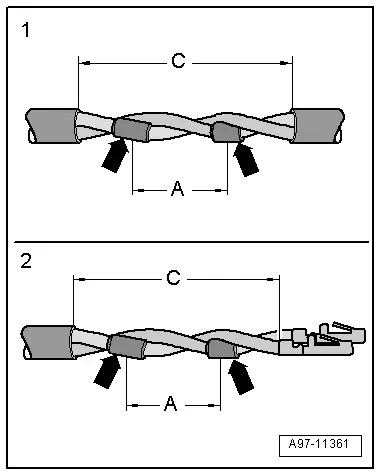

- During repair work, both wires must have the same length.

- When twisting the wires -1 and 2- together, the -A- = 30 mm routing length must be maintained.

- While doing so, no section of wire may be greater than -B- = 50 mm without twisting the wires, for example in the area of crimp connectors -arrow-.

- Maximum exposed wire length: -C- = 100 mm.

- Protect the area being repairs from the environment. Use a crimp connector with heat-shrinkable tube over the untwisted location being repairs and waterproof insulation over the exposed wire.

- Mark the location of the repair with something suitable, for example, with yellow tape.

- Repairing both wires is identical to repair just one wire.

- Position both repaired location -arrows--A- = 30 mm opposite each other.

- Crimp the cables with connectors.

1 - Repair location in the area without insulation

2 - Repair location with connectors

C - Maximum exposed length = 100 mm

Repair Kit for FlexRay Wires without Coating

Note

Note

- The repair of FlexRay wires without coating can only take place using FlexRay wires without coating from the Parts Catalog.

- Observe general notes for repairs on the vehicle electrical system. Refer to → Chapter "Vehicle Electrical System, General Repair Information".

Unshielded, twisted two-wire lines -1 and 2- with a cross section of 0.35 mm 2 can be used as FlexRay wires.

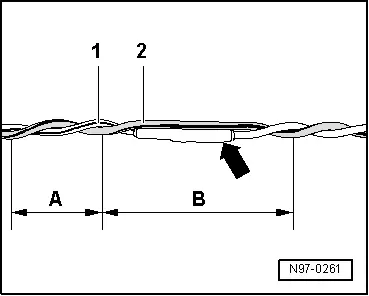

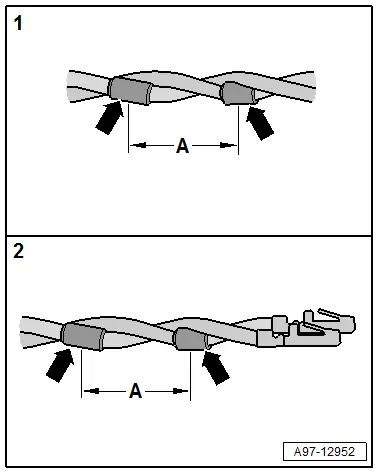

- During repair work, both FlexRay wires must have the same length.

- When twisting the wires -1 and 2- together, the -A- = 20 mm routing length must be maintained.

- While doing so, no section of wire may be greater than -B- = 40 mm without twisting the wires, for example in the area of crimp connectors -arrow-.

- Mark the location of the repair with something suitable, for example, with yellow tape.

- Repairing both FlexRay wires is identical to repairing just one wire.

- Position both repaired locations -A- = 20 mm opposite each other.

- Crimp the cables with connectors.

1 - Repair location in wiring harness

2 - Repair location with connectors

READ NEXT:

0.22 mm 2 Wire, Repairing with Individual

Crimp Connector

0.22 mm 2 Wire, Repairing with Individual

Crimp Connector

Procedure

- Free up the wire to be repaired approximately 20 cm on both

sides of the repair point.

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses c

Repairing a Wire 0.35 mm 2 or Greater with

Individual Crimp Connector

Repairing a Wire 0.35 mm 2 or Greater with

Individual Crimp Connector

Procedure

- Free up the wire to be repaired approximately 20 cm on both

sides of the repair point.

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses c

Repairing a 0.22 mm 2 Wire with Intermediate

Wire Section

Repairing a 0.22 mm 2 Wire with Intermediate

Wire Section

Note

For repairing a 0.222 a repair

wire can be used as the intermediate wire with a cross section

of 0.35-mm2 or 0.5-mm2.

Procedure

- Free up the wire to be repaired at two place

SEE MORE:

Introduction

Introduction

Depending on the vehicle equipment, various

parking aids will help you when parking and maneuvering.

Parking aid

The parking aid plus assists you while parking

using audio and visual signals to warn you about

objects detected in front of, behind, and next to

the vehicle.

The rearview camera shows t

Using Service Station

Using Service Station

General Information

Vehicles with a high-voltage system (hybrid vehicles)

Extremely Dangerous Due to High-Voltage

The high-voltage system is under high-voltage. Death or serious

bodily injury by electric shock.

- Individuals with electronic/medical life- and health sustaining

machines i

© 2019-2026 Copyright www.auq3.net