Audi Q3: CV Joint, Servicing, Drive Axle with Triple Roller Joint AAR3300i, Mounted in Transmission

Special tools and workshop equipment required

- Tripod Joint Tool -T10065-

- Puller - Driveshaft -T10382-

- Hose Clip Pliers -VAG1275A-

- Torque Wrench 1331 5-50Nm -VAG1331-

- Torque Wrench 1332 40-200Nm -VAG1332-

- Clamping Pliers -VAG1682A-

- Press Plate -VW401-

- Press Plate -VW402-

- Press Piece - Rod -VW408A-

- Press Piece - Multiple Use -VW411-

- Press Piece - 37mm -VW416B-

- Press Piece - Multiple Use -VW447H-

- Slide Hammer Set -VW771-

Removing the Outer CV Joint

- Clamp the drive axle with protective jaws in a vise clamp.

- Fold back boot.

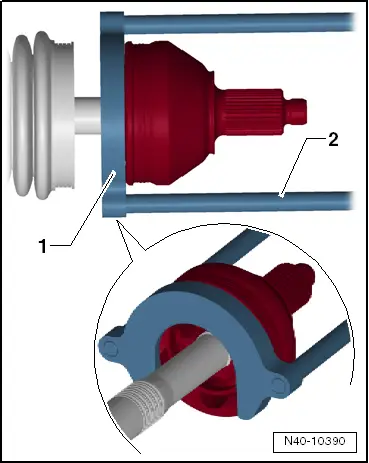

- Align the Puller - Driveshaft -T10382- so that the flat side of the Puller - Driveshaft - Removing Plate -T10382/1- faces the Puller - Driveshaft - Spindles -T10382/2-.

- Attach the Puller - Driveshaft -T10382- to the Slide Hammer Set -VW771-.

- Remove the CV joint from the drive axle using the Puller - Driveshaft -T10382- and Slide Hammer Set -VW771-.

1 - Puller - Driveshaft - Removing Plate -T10382/1-

2 - Puller - Driveshaft - Spindles -T10382/2-

Installing the Outer CV Joint

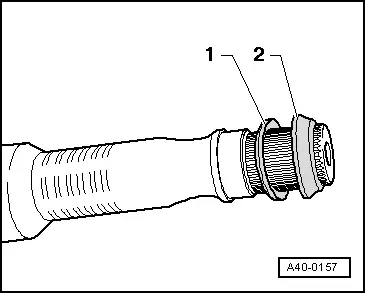

If installed, installed location of the spring washer and thrust washer on outer joint

1 - Plate Spring

2 - Thrust Ring

- Install the new circlips.

- Slide new CV boot onto drive axle if necessary.

- Use a plastic hammer to install it on the shaft until the locking ring locks secure.

Disassembling

- Open both clamps at inner joint and slide back CV boot.

- Remove joint from drive axle.

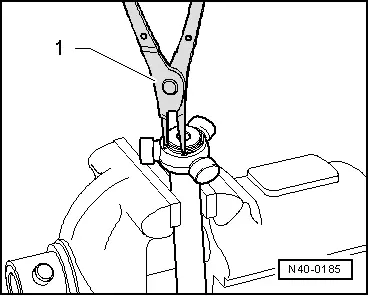

- Remove the circlip.

1 - Pliers (commercially available)

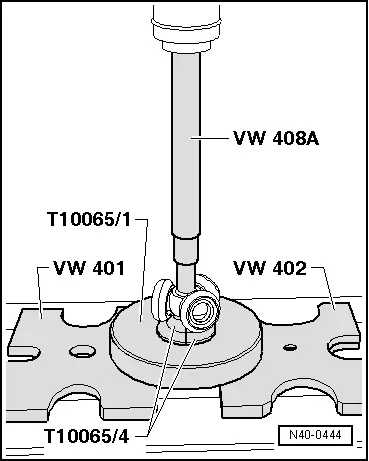

- Insert drive axle into the press.

- Press the triple roller star off the drive shaft.

- Pull off CV boot from shaft.

- Clean shaft, joint and groove for oil seal.

Assembling

- Slide small clamp for joint protective boot onto shaft.

- Slide CV boot onto shaft.

- Slide joint piece onto shaft.

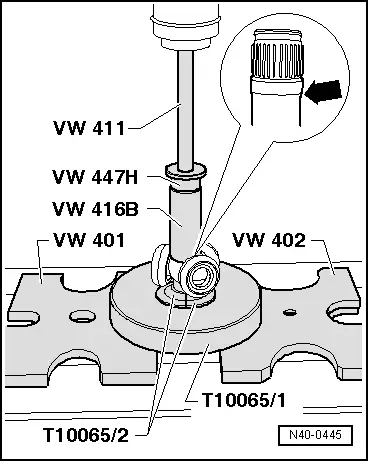

Triple Roller Star, Conical Drive Shaft, Installing

The chamfer on triple roller star faces toward shaft, this is used as an assembly aid.

- Install the triple roller star all the way onto the shaft.

- Make sure the pressure does not increase above 3.0 t.

- If necessary coat drive axle splines and triple roller star with Lubricating Paste -G 052 142 A2-.

- Insert securing ring, be sure to fit properly.

- Press half of the joint grease from the repair set into the triple roller joint.

- Slide joint piece over rollers and secure.

- Press the remaining half of the drive axle grease from the repair kit into the rear side of the triple roller joint.

- Install CV boot.

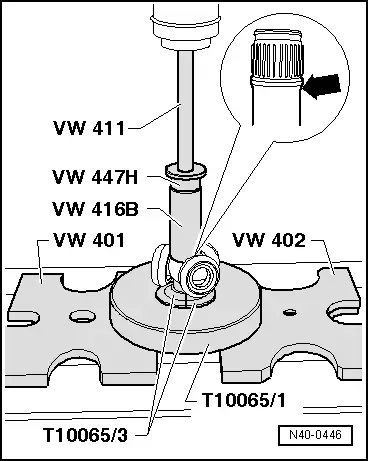

Triple Roller Star, Cylinder Drive Shaft, Installing

- Install the triple roller star all the way onto the shaft.

- Make sure the pressure does not increase above 3.0 t.

- If necessary coat drive axle splines and triple roller star with Lubricating Paste -G 052 142 A2-.

- Insert securing ring, be sure to fit properly.

- Press half of the joint grease from the repair set into the triple roller joint.

- Slide joint piece over rollers and secure.

- Press the remaining half of the drive axle grease from the repair kit into the rear side of the triple roller joint.

- Install CV boot.

- Slide the CV boot onto the joint and mount the clamp.

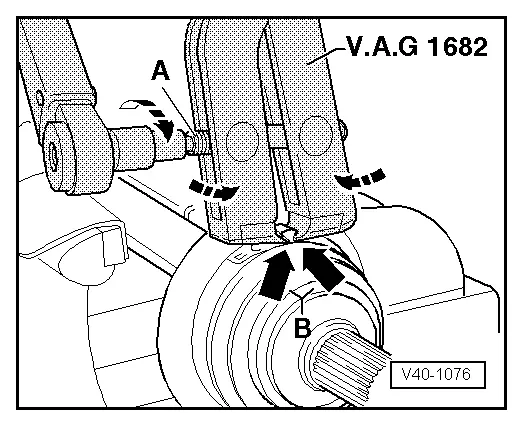

Tightening clamping sleeve on outer joint

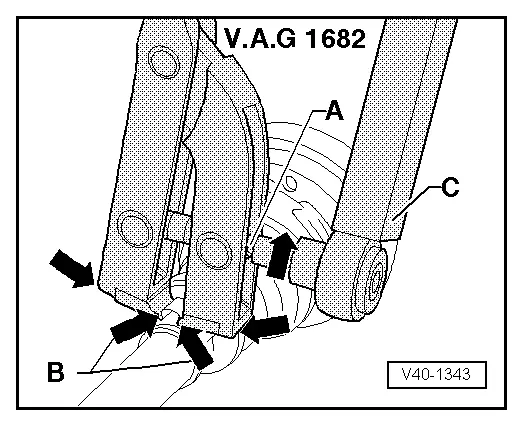

- Attach the Clamping Pliers -VAG1682A- as illustrated. When doing this, make sure that edges of clamping pliers are seated in corners -arrows B- of clamp.

- Tension clamp by turning spindle with a torque wrench (do not tilt Clamping Pliers -VAG1682A-).

Tensioning Clamp on Small Diameter

Note

Note

- The hard material of the CV boot (compared to rubber) makes it necessary to use a stainless steel hose clamp. It is only possible to tighten the hose clamp with Clamping Pliers -VAG1682A-.

- Tightening specification: 25 Nm.

- Use torque wrench -C- with adjustment range 5 to 50 Nm (for example Torque Wrench 1331 5-50Nm -VAG1331-).

- Make sure the threads on the spindle -A- on the pliers move easily. Lubricate with MOS 2 grease, if necessary.

- If the thread is tight, for example it is dirty, the required tensioning force for the hose clamp will not be achieved in spite of correct torque specification settings.