Audi Q3: 2.,5 mm2, 4 mm2 or 6 mm2 Aluminum Wires with Separate Butt Connectors, Repairing

Special tools and workshop equipment required

- Wiring Harness Repair Set - Hot Air Blower -VAS1978/14A- from the Wiring Harness Repair Set -VAS1978B-

- Wiring Harness Repair - Blower - Shrink Element -VAS1978/15A- from the Wiring Harness Repair Set -VAS1978B-

- Wiring Harness Repair Set -VAS631001-

Note

Note

- For the repair there are copper repair wires with a 2.5mm2 or 4 mm2 or 6 mm2 cross section.

- There are also separate copper repair wires with a crimped on contacts available for the repair.

Procedure

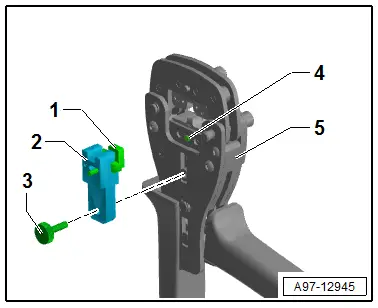

- Install the corresponding crimp insert, crimp stamp and contact positioner for the wire cross-section with the contact cross bar as follows on the crimping tool.

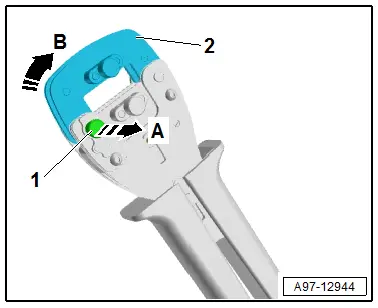

- Open the crimping tool from the Wiring Harness Repair Set -VAS 631 001-.

- Remove the locking pin -1- all the way in the direction of -arrow A-.

- Open the mount -2- in the direction of -arrow B-.

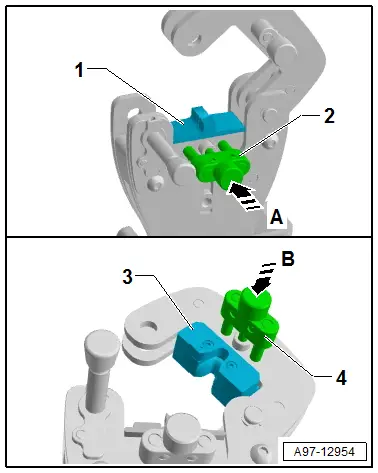

- Insert the crimp insert -1- in the crimping tool so that the crimp insert -1- is flush with the front of the clamps.

- Tighten the crimp insert with the pins -2- in direction of -arrow A- and the knurled screw hand tight.

- Insert the crimp stamp -3- that fits the crimp insert in the mount.

- Secure the crimp stamp with the pin -4- in direction of -arrow B- and the knurled screw hand-tight.

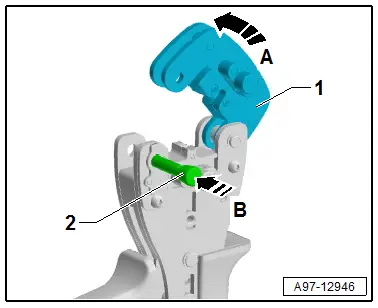

- Close the adapter -1- in the direction of -arrow A-.

- Push the locking pin -2- in the direction of -arrow- all the way.

- Insert the contact cross bar -1- in the contact positioner -2-.

- Position the contact positioner with the contact cross bar on the crimping tool -5- at the same time push the holes in the contact positioner -2- over the knurled screw -4-.

- Install the knurled bolt -3- and tighten hand-tight.

- Free up the wire to be repaired approximately 20 cm on both sides of the repair point.

Caution

Caution

Risk of damaging the electrical wires.

Expose wrapped wiring harnesses carefully.

- If necessary, removing the wiring harness wrapping using a knife.

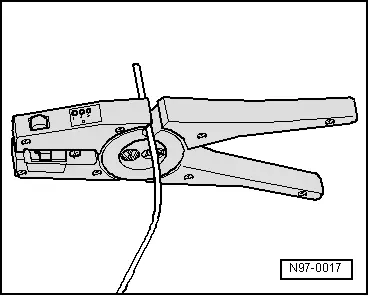

- Cut the damaged section of the wire with wire stripper from the Wiring Harness Repair Set -VAS 631 001-.

Note

Note

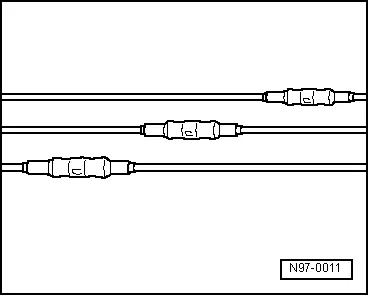

When both ends of the vehicle-specific single wire are too short after cutting out the damaged wire section for a repair with a separate butt connector, insert a corresponding long piece of yellow copper repair wire with two butt connectors.

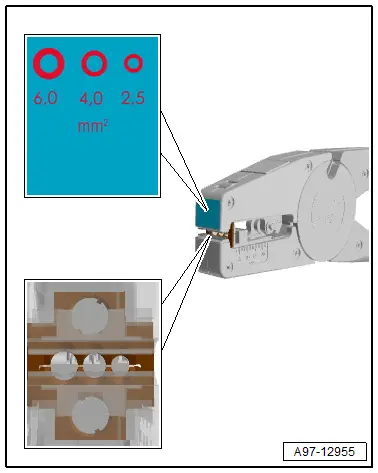

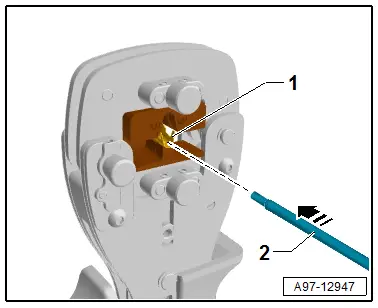

- Insert the wire end from the front all the way in to the wire cross-section corresponding mount in the jaws of the pliers.

- Push the pliers completely together.

- Open pliers again and remove the stripped wire end.

- The insolation must be cut cleanly and remove from the wires.

- No insolation can remain on bare wires.

- The single wires must not be damaged.

- For the repair remove the corresponding butt connection with a heat-shrinkable tube from the Wiring Harness Repair Set -VAS 631 001-.

- Push the heat-shrinkable tube on one of the wires.

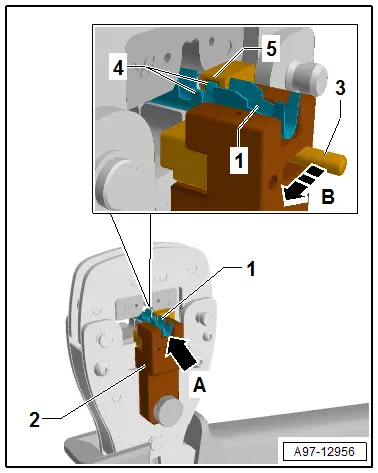

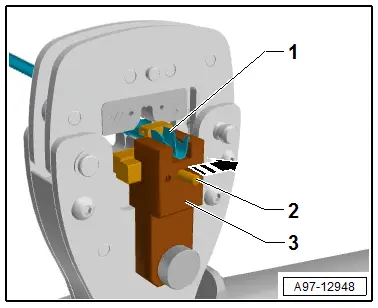

- Place the butt connection -1- in the contact positioner -2-.

- The butt connection -1- must be flush with the contact positioner -2--arrow A-.

- Push the contact cross bar -3- all the way in the direction of the -arrow B- and secure it with the butt clamp -1-.

- The tab -4- on the butt connection -1- must engage in the groove -5- on the contact cross bar -3-.

- Insert the wire -2- with the bare wire end all the way in the butt connection -1--arrow-.

- All single wires must be pushed into the butt connection.

- The insolation end can at a maximum be flush with the front edge of the insolation crimps.

- Close the crimping tool completely until it reopens by itself.

- Push the contact cross bar -2- all the way in the direction of -arrow-.

- Remove the butt connection -1- from the contact positioner -3-.

- Turn the crimping tool for the second crimping.

- Repeat the wire crimping on the other side as described.

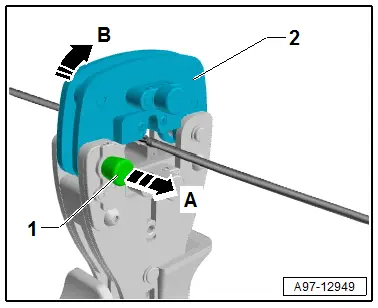

- Remove the securing pin -1- in the direction of -arrow A- until it stops.

- Open the mount -2- in the direction of -arrow B-.

- Remove the crimped butt connectors.

Correct crimping results

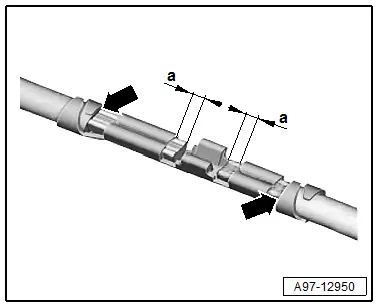

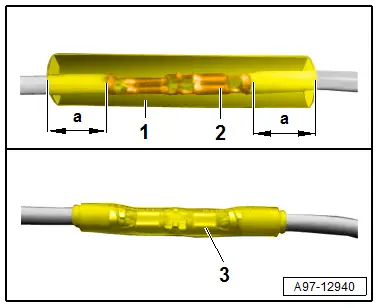

- The wire ends must project 0.1 mm to 1.0 mm on the front edge of the wire crimps, dimension -a-

- The insolation end must not be crimped in the wire crimps.

- The insolation end can at a maximum be flush with the front edge of the insolation crimps -arrows-.

After crimping the heat-shrinkable tube must positioned over the butt connection and heat-shrunk with a hot air gun, to prevent moisture from entering.

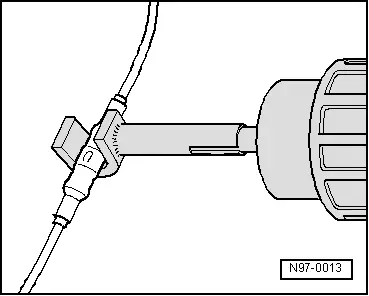

- Insert the Wiring Harness Repair - Blower - Shrink Element -VAS 1978/15A- on the Wiring Harness Repair Set - Hot Air Blower -VAS 1978/14A-.

Caution

Caution

Risk of damaging surrounding components.

- When heat-shrinking the heat-shrinkable tube, be careful not to damage any other wiring, plastic parts or insulating material with the hot nozzle of the hot air blower.

- Always observe operating instructions of heat gun.

- Position the heat-shrinkable tube -1- centered over the butt connection -2-.

- The dimension -a- must be approximately the same on both sides

- Heat the heat-shrinkable tube using the hot air blower lengthwise from center outward until it is sealed completely and adhesive comes out the ends.

- The completed repair location -3- must look like so.

Note

Note

- Make sure that the butt connections do not lie directly next to each other when several wires need to be repaired. Arrange the butt connection at a slight offset so that the circumference of the wiring harness does not become too large.

- If the repair point was previous taped, this point must be taped again with yellow insulating tape after repairs.

- Secure the repaired wiring harness if necessary with a cable tie to prevent flapping noises while driving.